Specialty Materials SWD foam&sculpture solvent free hand applied polyurea coating – SWD

Specialty Materials SWD foam&sculpture solvent free hand applied polyurea coating – SWD Detail:

Characteristics

♢SWD solvent free styrofoam polyurea coating is easy to apply, no special machine needed, small scraper or brush method is good.

♢Curing at normal temperature, the coating has excellent adhesive strength with many substrates, the surface is smooth and flat.

♢Membrane has good flexibility, good waterproofing performance, excellent impact resistance and abrasion resistance.

Specifications

| Adhesive force (concrete base) | 2.5Mpa(or base material break) |

| Hardness | Shore A: 50-95, Shore D:60-80(or according to customers’ requirement) |

| Tensile strength | 10~20Mpa |

| Elongation | 100-300% |

| Temperature variation resistance | -40——+120℃ |

| Abrasive resistance(700g/500r) | 7.2mg |

| Acid resistance | |

| 10%H2SO4 or 10%HCI,30d | no rust no bubbles no peel off |

| Alkali resistance 10%NaOH,30d | no rust no bubbles no peel off |

| Salt resistance 30g/L,30d | no rust no bubbles no peel off |

| Salt spray resistance,1000h | no rust no bubbles no peel off |

| Environmental Rank | cured coating is qualified to food grade |

Data of performance

| Color | Multiple colors as customers’ need |

| Luster | Glazed |

| Density | 1.25g/cm³ |

| Volume solid content | 99%±1% |

| VOC | 0 |

| Matching ratio by weight | A:B=1:1 |

| Recommended dry film thickness | According to customer requirement |

| Theoretical coverage | 1.3kg/sqm (calculated by the above solids percentage and dry film thickness of 1000 microns) |

| Practical coverage | Allow appropriate loss rate |

| Tack Free | 60~90min |

| Overcoating interval | Min 3h; Max24h |

| Overcoating method | Brush, scratch |

| Flash point | 200℃ |

Shelf life

At least 6 months(Indoor with dry and cool conditions)

Chemical resistance

| Acid resistance 40%H2SO4 or 10%HCI, 240h | no rust, no bubbles, no peel off |

| Alkali resistance 40%NaOH, 240h | no rust, no bubbles, no peel off |

| Salt resistance 60g/L, 240h | no rust, no bubbles, no peel off |

| Salt spray resistance 1000h | no rust, no bubbles, no peel off |

| Oil resistance, engine oil 240h | no rust, no bubbles, no peel off |

| Water resistance, 48h | No bubbles, no wrinkled,no color-changing, no peel off |

| (Note: The above chemical resistant property is obtained according to the GB/T9274-1988 test method, for reference only. Pay attention to the influence of ventilation, splash and spillage. Independent immersion testing is recommended if requires other specific data.) | |

Packing

part A: 5kg/bucket; part B: 5kg/bucket

Production area

Minhang Shanghai City, and Nantong coastal industrial park production base in Jiangsu(15% of the raw materials imported from SWD US, 85% from domestic)

Security

To apply this product must be accordance with the relevant national regulation of sanitation, safety and environment protection. Do not even contact the surface of wet coating.

Global applicability

Our company aims to provide worldwide customers with standard coating products, however custom adjustments can be made to adapt and leverage different regional conditions and international norms. In this case, additional alternative product data will be provided.

Integrity declaration

Our company guarantees the reality of the listed data,due to the diversity and variability of the application environment, please test and verify it before use. We don’t take any other responsibilities except the coating quality self and reserve the right of modifying the listed data without prior notice.

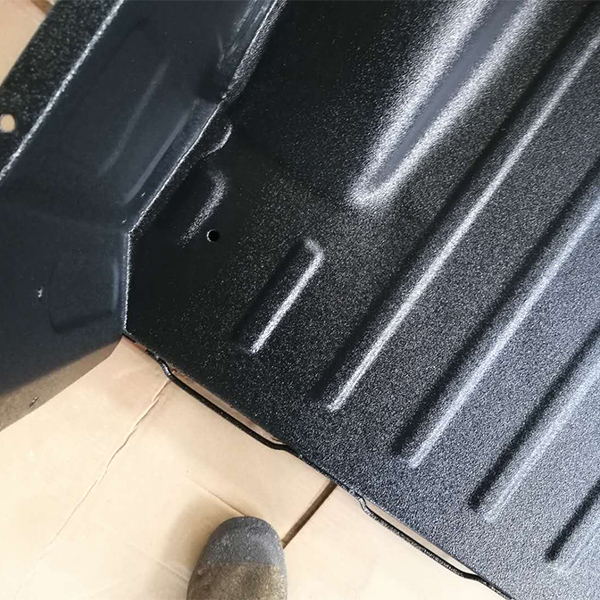

Product detail pictures:

Related Product Guide:

Usually customer-oriented, and it's our ultimate focus on to be not only by far the most reliable, trustable and honest provider, but also the partner for our customers for Specialty Materials SWD foam&sculpture solvent free hand applied polyurea coating – SWD , The product will supply to all over the world, such as: French, Mauritius, Congo, With the goal of "zero defect". To care for the environment, and social returns, care employee social responsibility as own duty. We welcome friends from all over the world to visit and guide us so that we can achieve the win-win goal together.

The customer service staff is very patient and has a positive and progressive attitude to our interest, so that we can have a comprehensive understanding of the product and finally we reached an agreement, thanks!