OEM Two Component Spray Foam Manufacturers – SWD250 Spray Rigid Polyurethane Foam Building walls heat insulation material – SWD

OEM Two Component Spray Foam Manufacturers – SWD250 Spray Rigid Polyurethane Foam Building walls heat insulation material – SWD Detail:

Characteristics

SWD250 external wall rigid polyurethane foam is a new energy efficient insulation material which is instant sprayed-forming by A & B liquid under high pressure of spray gun. The liquid material has good fluidity and permeability under high pressure that be able to keep foaming inside the wall and firmly bond with the base to seal gaps. The adhesive strength(≥40Kpa) bonded with the base surpasses the tear strength of the rigid foam self, it will not peel off even the substrate occurs expansion and contraction. This product is acid and alkali resistant, solvent resistant and anti-aging, the service life is over 50 years which is fit for the service cycle of the building exterior walls and resolved all the problems of traditional materials’ frequent maintenance from water absorption, moisture absorption and leaking. SWD250 is environment-friendly safe applied with newly Eco friendly foaming agent that is solvent free, no volatile and no pollution in production and application process.

Specifications

| Density | ≥35kg/㎥ |

| compressive strength | ≥0.2Mpa |

| heat conductivity coefficient | ≤0.022W/(m.k) |

| Water absorption rate v/v | ≤2% |

| Dimensional stability(70℃ 48h) | ≤1% |

| Closed-cell rate | ≥95% |

| combustion performance | B2 class |

The heat insulation effect fully meets and better than the requirements of heating residential parts in JGJ26-89 residential building energy efficient design standard. The fire retardant performance complies with GBJ16 Building Design Fire retardant code.

Recommended procedures

| No. | Performance process |

| 1 | leveling the exterior wall substrate |

| 2 | clear up the exterior wall with no dust and Debris |

| 3 | brush the coating slurry |

| 4 | spray polyurethane rigid foam per instruction. |

| 5 | stick on the mesh cloth |

| 6 | use anti-crack putty to flat the surface |

| 7 | brush coatings or stick tiles. |

Typical physical properties

| Item | Test standard | Results |

| Pencil hardness | H | |

| Adhesive strength(Mpa)metal base | HG/T 3831-2006 | 9.3 |

| Adhesive strength(Mpa)concrete base | HG/T 3831-2006 | 2.8 |

| Impermeability | 2.1Mpa | |

| Bending test (cylindrical shaft) | ≤1mm | |

| Abrasion resistance (750g/500r) mg | HG/T 3831-2006 | 5 |

| Impact resistance kg·cm | GB/T 1732 | 50 |

| Anti-aging, accelerated aging 1000h | GB/T14522-1993 | Loss of light<1, chalking <1 |

Application scope

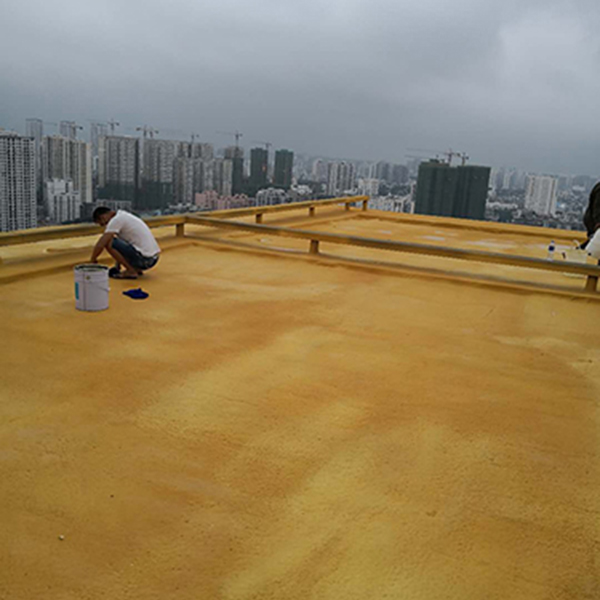

heat insulation of building walls and roof

Shelf life

10 months (indoor with dry and cool conditions)

Packing

A component 250kg/bucket; B component 200kg/bucket.

Production places

Minhang Shanghai City, and Nantong coastal industrial park production base in Jiangsu (5% of the raw materials imported from SWD US, 60% from multinational company in Shanghai, 35% from local support)

Security

To apply this product must be accordance with the relevant national regulation of sanitation, safety and environment protection. Do not even contact the surface of wet coating.

Global applicability

Our company aims to provide worldwide customers with standard coating products, however custom adjustments can be made to adapt and leverage different regional conditions and international norms. In this case, additional alternative product data will be provided.

Integrity declaration

Our company guarantees the reality of the listed data. Due to the diversity and variability of the application environment, please test and verify it before use. We don’t take any other responsibilities except the coating quality self and reserve the right of modifying the listed data without prior notice.

Product detail pictures:

Related Product Guide:

Well-run products, skilled income group, and better after-sales products and services; We have been also a unified massive family, all people stick with the business price "unification, dedication, tolerance" for OEM Two Component Spray Foam Manufacturers – SWD250 Spray Rigid Polyurethane Foam Building walls heat insulation material – SWD , The product will supply to all over the world, such as: Malawi, Hyderabad, Iceland, The credibility is the priority, and the service is the vitality. We promise we have the ability to provide excellent quality and reasonable price products for customers. With us, your safety is guaranteed.

The company has rich resources, advanced machinery, experienced workers and excellent services, hope you keep improving and perfecting your products and service, wish you better!