OEM Polyurea Flake Floor Suppliers – SWD9514 Movie props appliance and speaker special polyurea protective coating – SWD

OEM Polyurea Flake Floor Suppliers – SWD9514 Movie props appliance and speaker special polyurea protective coating – SWD Detail:

Product features and advantages

*Solvent free, 100% solid content, safe, environmentally friendly and odor free.

*Rapid cure, can be sprayed forming on any bent, slope and vertical surfaces, no sagging.

*Coating film is compact, dense and flexibility, high adhesive strength with wood and foam substrate.

*Excellent impact resistance, collision resistance and abrasion resistance

*Excellent anticorrosion and chemical resistance to acids, alkali, salts etc.

*Good shock absorbing performance

*Excellent waterproof and moisture proof performance

*Excellent resistance to temperature variation

*Fast cure, application site back to service quickly

*Excellent durability to reduce maintenance cost of service life

*Extend the service life of sprayed structure

Application scopes

Wearable anticorrosion protection of coal chute, spiral separator, flotation tank, washing drum, transmission belt and other mining facilities.

Product information

| Item | A | B |

| Appearance | Pale yellow liquid | Adjustable color |

| Proportion(g/m³) | 1.13 | 1.04 |

| Viscosity(cps)@25℃ | 650 | 720 |

| Solid content (%) | 100 | 100 |

| Mixing ratio(volume ratio) | 1 | 1 |

| Gel time(second)@25℃ | 3-5 | |

| Dry time(second) | 10-20 | |

| Theoretical Coverage(dry film thickness) | 1.03kg/㎡ film thickness:1mm | |

Physical properties of products

| Items | Test standard | Result |

| Hardness (Shore D) | ASTM D-2240 | 47 |

| Elongation rate(%) | ASTM D-412 | 150 |

| Tensile strength(Mpa) | ASTM D-412 | 20 |

| Tear strength (N/km) | ASTM D-624 | 65 |

| Impermeability(0.3Mpa/30min) | HG/T 3831-2006 | impermeable |

| Wear resistance (750g/500r)/mg | HG/T 3831-2006 | 4.5 |

| Adhesive strength(Mpa)concrete base | HG/T 3831-2006 | 3.1 |

| Adhesive strength(Mpa) steel base | HG/T 3831-2006 | 11 |

| Density(g/cm³) | GB/T 6750-2007 | 1.02 |

| Cathodic disbondment [1.5v,(65±5)℃,48h] | HG/T 3831-2006 | ≤15mm |

Product corrosion medium

| Acid resistance 10%H2SO4 or 10%HCI,30d | No rust, no bubbles, no peel off |

| Alkali resistance 10% NaOH, 30d | No rust, no bubbles, no peel off |

| Salt resistance 30g/L,30d | No rust, no bubbles, no peel off |

| Salt spray resistance, 2000h | No rust, no bubbles, no peel off |

| Oil resistance 0# diesel, crude,30d | No rust, no bubbles, no peel off |

| (For reference: the above data is acquired based on GB / T9274-1988 test standard. Pay attention to the influence of ventilation, splash and spillage. Independent immersion testing is recommended if requires other specific data) | |

Product application environment

| Environment temperature | 0℃-45℃ |

| Product spray heating temperature | 65℃-70°C |

| Pipe heating temperature | 55℃-65℃ |

| Relative humidity | ≤75% |

| Dew point | ≥3℃ |

Product application guide

| Recommend spray machine | GRACO H-XP3 Polyurea spray equipment |

| Spray gun | Air or machine self-cleaning coatings for spray gun |

| Static pressure | 2300-2500psi |

| Dynamic pressure | 2000-2200psi |

| Recommend film thickness | 1000-3000μm |

| Recoating interval | ≤6h |

Application note

Agitate part B uniform prior to application, thoroughly mix the deposited pigments, or the product quality will be affected.

spray polyurea within the proper time if the substrate surface is primed. For the application method and interval time of SWD polyurea speical primer please refer to SWD companies’ other brochure.

Always apply SWD spray polyurea on a small area before large application to check the mix ratio, color and spray effect are correct. For detailed information of application please refer to the latest instruction sheet of the application instructions of SWD spray polyurea series.

Product cure time

| Substrate temperature | Dry | Foot traffic | Solid dry |

| +10℃ | 20s | 45min | 7d |

| +20℃ | 15s | 15min | 6d |

| +30℃ | 12s | 5min | 5d |

Note: the curing time varies with the environment condition especially the temperature and relative humidity.

Shelf life

*From the manufacturer date and on the original package sealed condition:

A:10 months

B:10 months

*storage temperature:+5-35°C

Packing: Part A 210kg/drum, part B 200kg/drum

Make sure the product package sealed well

* store in cool and ventilated place, avoid direct sunshine exposure.

Product health and safety information

For information and advice on the safe handling, storage and disposal of chemical products, users shall refer to the most recent Material Safety Data Sheet containing physical, ecological, toxicological and other safety related data.

Integrity declaration

SWD guarantee all technical data stated in this sheet are based on laboratory tests. Actual testing methods may vary due to different circumstances. Therefore please test and verify its applicability. SWD does not take any other responsibilities except the product quality and reserve the right of any modifications on the listed data without prior notice.

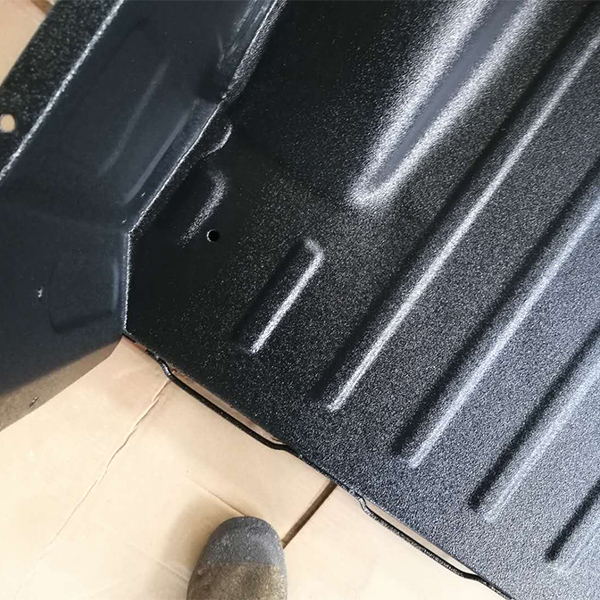

Product detail pictures:

Related Product Guide:

Our solutions are widely regarded and trustworthy by consumers and may meet continually modifying financial and social requirements for OEM Polyurea Flake Floor Suppliers – SWD9514 Movie props appliance and speaker special polyurea protective coating – SWD , The product will supply to all over the world, such as: Belgium, Montpellier, Croatia, During in 11 years,We have participated in more than 20 exhibitions,obtains the highest praise from each customer. Our company always aim to provide the customer best products with lowest price. We are making great efforts to achieve this win-win situation and sincerely welcome you to join us. Join us, show your beauty. We will always be your first choice. Trust us, you will never lose heart.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!