OEM Liquid Polyurethane Foam Insulation Products – SWD959 moisture cure polyurethane industrial anticorrosion protective coating – SWD

OEM Liquid Polyurethane Foam Insulation Products – SWD959 moisture cure polyurethane industrial anticorrosion protective coating – SWD Detail:

Features and benefits

* excellent adhesive strength, bond solid with carbon steel, concrete and other substrates.

* coating membrane is dense and flexible, to withstand the damage of cyclic stress failure

* high solid content and meet the requirements of environmentally friendly

*excellent mechanical property, abrasion resistance, impact resistance and scratch resistance

*excellent waterproof

*excellent anticorrosion property and resistance to many chemical rust medium such as salt spray, acid rain.

*excellent anti-aging, no crack and no powder after long term outdoor use.

*hand brushable coating, easy to apply, multiple application method is suitable

*single component, easy application without need of mix ratio with other parts.

Typical use

Anticorrosion waterproof protection in the industrial enterprises of oil, chemistry, transportation, construction, power plant etc.

Product information

| Item | Results |

| Appearance | Color adjustable |

| Viscosity (cps )@20℃ | 250 |

| Solid content (%) | ≥65 |

| surface dry time (h) | 2-4 |

| Pot life (h) | 1 |

| theoretical coverage | 0.13kg/m2(thickness 100um) |

Physical property

| Item | Test standard | Results |

| pencil hardness | GB/T 6739-2006 | 2H |

| bending test (cylindrical mandrel) mm | GB/T 6742-1986 | 1 |

| breakdown resistance strength (kv/mm) | HG/T 3330-1980 | 250 |

| impact resistance (kg·cm) | GB/T 1732 | 60 |

| resistance to temperature changes (-40–150℃) 24h | GB/9278-1988 | Normal |

| adhesive strength (Mpa), metal base | ASTM D-3359 | 5A (highest) |

| density g/cm3 | GB/T 6750-2007 | 1.03 |

Chemical resistance

| Acid resistance 50% H2SO4 or15%HCl, 30d | No rust, no bubbles, no peel off |

| Alkali resistance 50%NaOH, 30d | No rust, no bubbles, no peel off |

| Salt resistance, 50g/L,30d | No rust, no bubbles, no peel off |

| Salt spray resistance, 2000h | No rust, no bubbles, no peel off |

| Oil resistance 0# diesel, crude oil, 30d | No bubbles, no peel off |

| ( For reference: pay attention to the influence of ventilation, splash and spillage. Independent immersion testing is recommended if requires other specific data.) | |

Application environment

Relative temperature: -5~-+35℃

Relative humidity: RH%:35-85%

Dew point: the temperature of metal surface must have 3℃ than dew point.

Application tips

Recommended dft: 100-200 (as design requirement)

Surface preparation: sand-blasting to above Sa2.5 degree, or polish to St3 class with electric tools.

Re-coating interval: 4-24h, if the interval time exceed 24h or has dust deposited, sand-blasting first and clean well prior to application.

Coating method: airless spray, air spray, brush, roller

Application note

It can be applied in the low temperature below 10℃. Put the coating bucket into the air-conditioning room for over 24 hours when apply in the low temperature environment.

SWD recommends to agitate the coating uniform prior to application, pour accurate quantity of material to another vessel and seal well immediately. Don’t pour the rest liquid to the original bucket.

The viscosity of product is set up in the factory, thinner shall not be random added by the applicators. Call the manufacturer for the instructions of special thinner if the viscosity changed as the application environment and humidity.

Curing time

| Substrate temperature | Surface dry time | Foot traffic | Solid dry |

| +10℃ | 6h | 24h | 7d |

| +20℃ | 3h | 12h | 6d |

| +30℃ | 2h | 8h | 5d |

Shelf life

* storage temperature: 5℃-32℃

* shelf life: 12 months (sealed)

* store in cool and ventilated place, avoid direct sunshine, keep away from heat

* package: 5kg/bucket, 20kg/bucket, 25kg/bucket

Product health and safety information

For information and advice on the safe handling, storage and disposal of chemical products, users shall refer to the latest Material Safety Data Sheet containing physical, ecological, toxicological and other safety related data.

Integrity declaration

SWD guarantee all technical data stated in this sheet are based on laboratory tests. Actual testing methods may vary due to different circumstances. Therefore please test and verify its applicability. SWD does not take any other responsibilities except the product quality and reserve the right of any modifications on the listed data without prior notice.

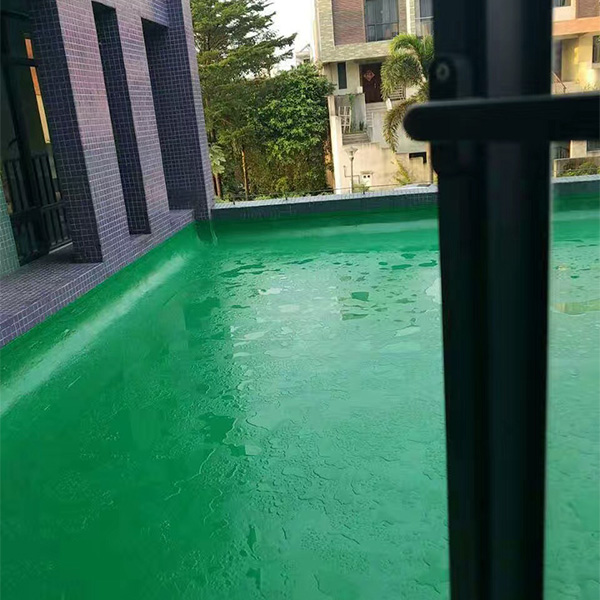

Product detail pictures:

Related Product Guide:

It can be a great way to enhance our solutions and service. Our mission would be to build inventive products to consumers with a superior working experience for OEM Liquid Polyurethane Foam Insulation Products – SWD959 moisture cure polyurethane industrial anticorrosion protective coating – SWD , The product will supply to all over the world, such as: Egypt, Iraq, French, You can let us know your idea to develop unique design for your own model to prevent too much similar parts in the market! We will provide our best service to satisfy all your needs! You should contact us right away!

Company director has very rich management experience and strict attitude, sales staff are warm and cheerful, technical staff are professional and responsible,so we have no worry about product,a nice manufacturer.