Low Pressure Spray SWD9522 single component polyurea industrial wearable anticorrosion floor coating – SWD

Low Pressure Spray SWD9522 single component polyurea industrial wearable anticorrosion floor coating – SWD Detail:

Product features and advantages

*High solids, low VOC emissions

*Easy to apply, brush, roller, air spray or airless spray all suitable.

*High physical properties of wearable, impact resistance and scratch resistance

*Excellent waterproof performance

*Excellent chemical resistance, can withstand certain concentration of acid, alkali, salt, oil, organic solvents etc.

*Excellent adhesion force, fast bonding well on the surface of steel, concrete, wood, fiberglass and other substrates.

*Wide temperature requirements, can be used in environments of -50 ℃ ~ 120℃.

*One component material, easy operation without ratio mixed, reducing labor costs

Typical use

Flooring of oil chemical plant, cotton processing factory, pharmaceutical factory, brewery plant, food processing plants, dairy plants, iron and steel manufacturing enterprises, power plant, machinery processing factory, workshop and warehouse floor of pesticide production industry

Product information

| Item | results |

| Appearance | Color adjustable |

| Specific gravity (g/m³) | 1.15 |

| Viscosity (cps)@20℃ | 420 |

| Solid content (%) | ≥75 |

| Dry time(hour) | 1-3 |

| Pot life (h) | 1h |

| Theoretical Coverage | 0.15kg/m2 (thickness:100um) |

Physical properties of products

| Item | Test standard | Result |

| Hardness (Shore A) | ASTM D-2240 | 85 |

| Elongation (%) | ASTM D-412 | 410 |

| Tensile strength(Mpa) | ASTM D-412 | 22 |

| Tear strength (kN/m) | ASTM D-624 | 63 |

| Wear resistance (750g/500r)/mg | HG/T 3831-2006 | 7 |

| Adhesive strength (Mpa), metal base | HG/T 3831-2006 | 11 |

| Adhesive strength (Mpa), concrete base | HG/T 3831-2006 | 3.2 |

| Impact resistance(kg.m) | GB/T23446-2009 | 1.0 |

| Density(g/cm³) | GB/T 6750-2007 | 1.1 |

Chemical resistance

| Acid resistance 30% H2SO4 or 10%HCI, 30d | No rust, no bubbles, no peel off |

| Alkali resistance 30% NaOH, 30d | No rust, no bubbles, no peel off |

| Salt resistance 30g/L,30d | No rust, no bubbles, no peel off |

| Salt spray resistance,2000h | No rust, no bubbles, no peel off |

| Oil resistance 0# diesel,crude oil, 30d | No rust, no bubbles, no peel off |

| ( For reference: pay attention to the influence of ventilation, splash and spillage. Independent immersion testing is recommended if requiring detail data.) | |

Product application environment

Relative temperature: -5~-+35℃

Relative humidity: RH%:35-85%

Dew point: the temperature of metal surface must have 3℃ than dew point.

Application tips

Recommended dft: 100-200 (as design requirement)

Re-coating interval: 4-24h, if the interval time exceed 24h or has dust deposited, sand-blasting first and clean well prior to application.

Coating method: airless spray, air spray, brush, roller

Curing time

| Substrate temperature | Surface dry time | Foot traffic | Solid dry time |

| +10℃ | 6h | 24h | 7d |

| +20℃ | 3h | 12h | 6d |

| +30℃ | 2h | 8h | 5d |

Shelf life

* storage temperature: 5℃-32℃

* shelf life: 12 months (sealed)

* store in cool and ventilated place, avoid direct sunshine, keep away from heat

* package: 5kg/bucket, 20kg/bucket, 25kg/bucket

Product health and safety information

For information and advice on the safe handling, storage and disposal of chemical products, users shall refer to the latest Material Safety Data Sheet containing physical, ecological, toxicological and other safety related data.

Integrity declaration

SWD guarantee all technical data stated in this sheet are based on laboratory tests. Actual testing methods may vary due to different circumstances. Therefore please test and verify its applicability. SWD does not take any other responsibilities except the product quality and reserve the right of any modifications on the listed data without prior notice.

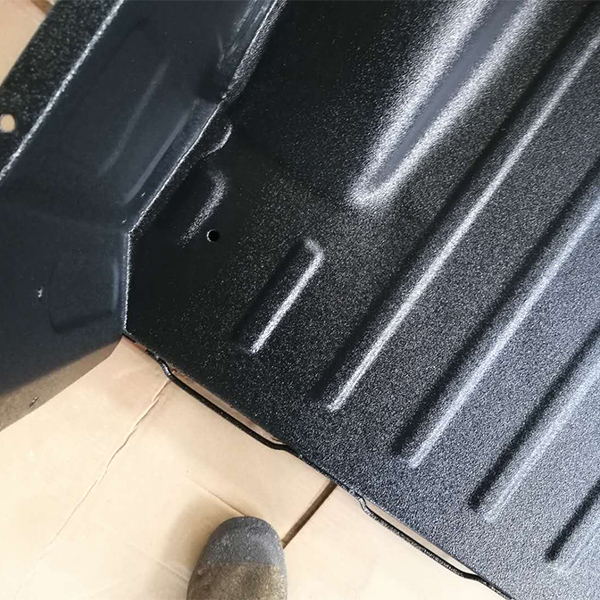

Product detail pictures:

Related Product Guide:

As a way to finest meet up with client's wants, all of our operations are strictly performed in line with our motto "High Quality, Aggressive Price, Fast Service" for Low Pressure Spray SWD9522 single component polyurea industrial wearable anticorrosion floor coating – SWD , The product will supply to all over the world, such as: New Zealand, Latvia, Costa Rica, We pursue the management tenet of "Quality is superior, Service is supreme, Reputation is first", and will sincerely create and share success with all clients. We welcome you to contact us for more information and look forward to working with you.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.